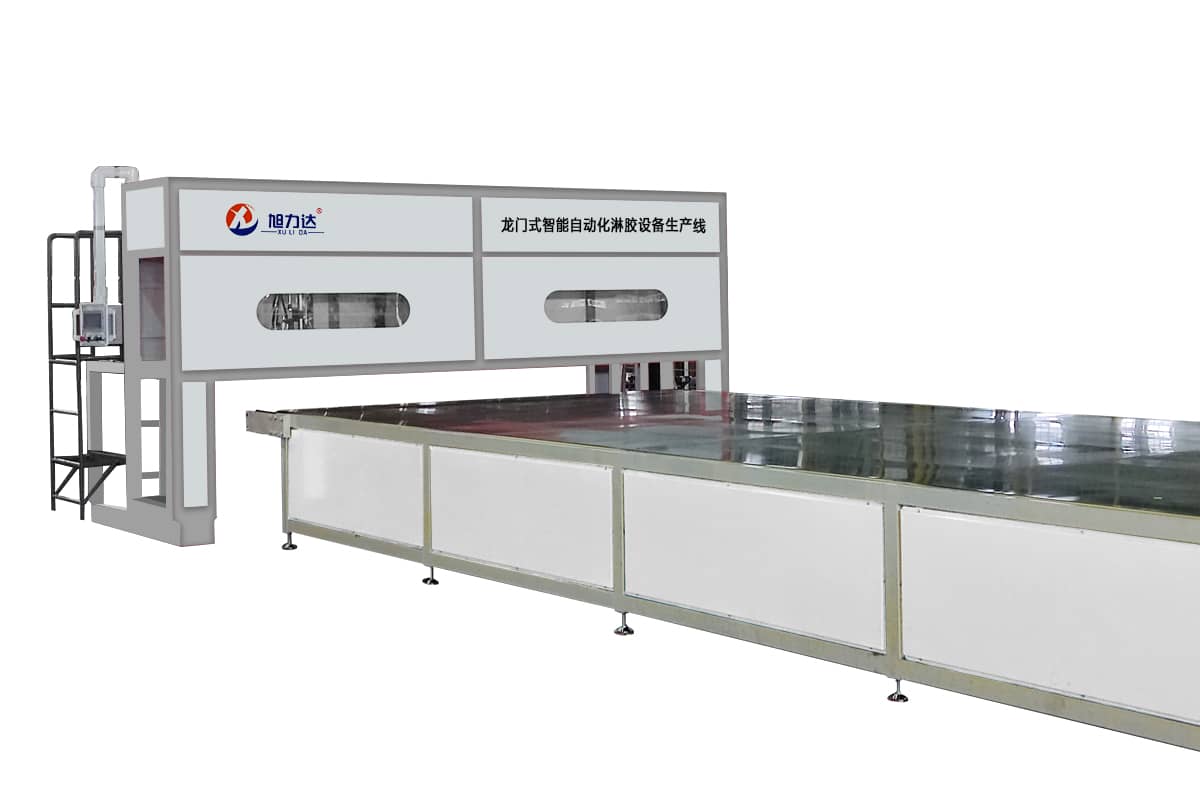

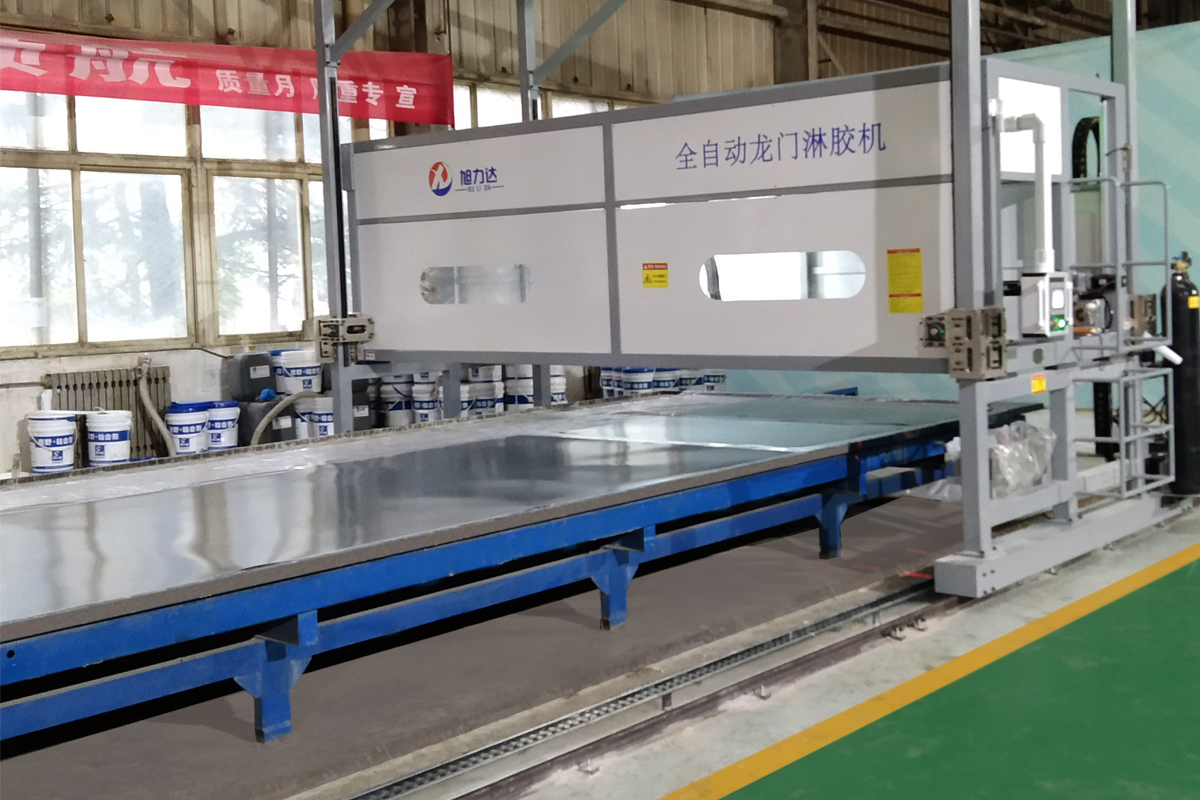

Gantry Glue Spraying Machine

Analysis of Automatic Coating and Manual Scraping Processes

| Category | Automatic Coating | Manual Scraping | Remarks | ||||||||||

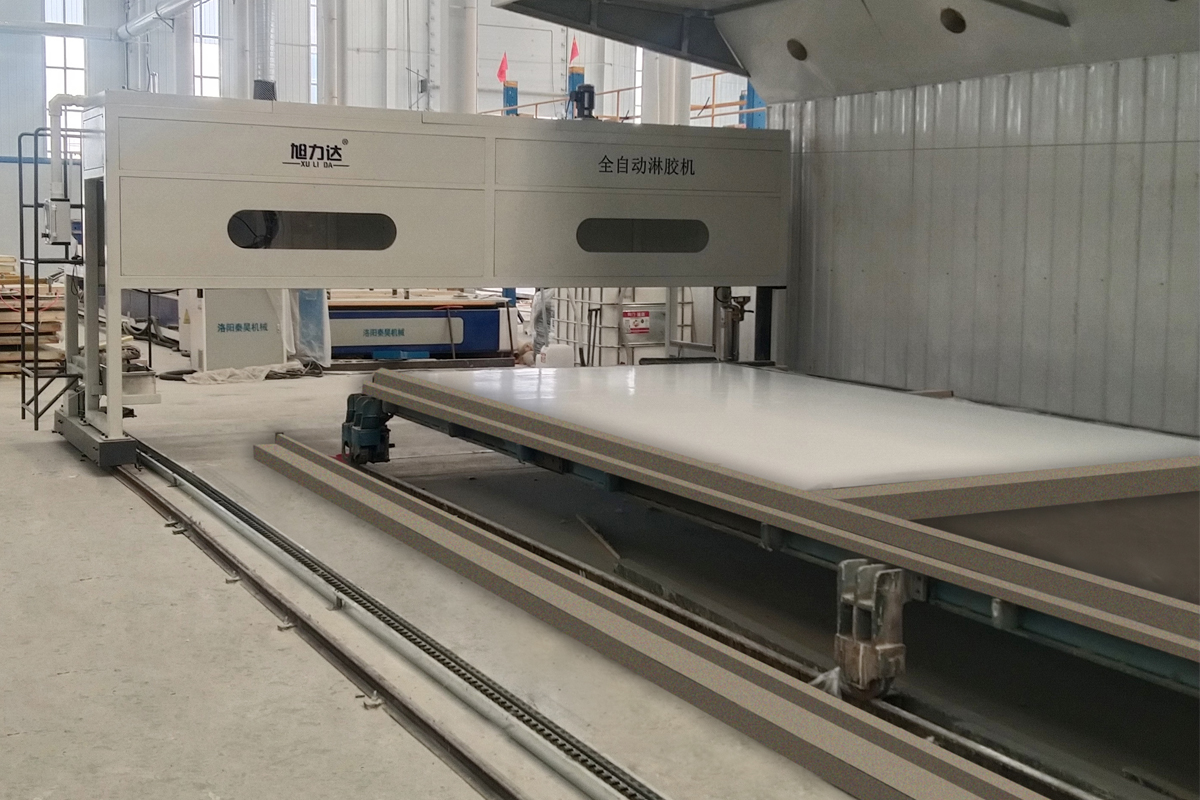

| Coating Method | Single operator can complete automatic proportioning, glue mixing and glue spraying | Requires at least 3-4 people for mixing and scraping, and the scraping is uneven | Operating the equipment does not require glue mixing and glue brushing workers, only compounding workers are needed. | ||||||||||

| Glue Application Precision | In the coating process, the distance from the edges of the board can be controlled to prevent glue spillage and ensure aesthetic appearance | Manual coating can lead to edge contamination due to uneven application | |||||||||||

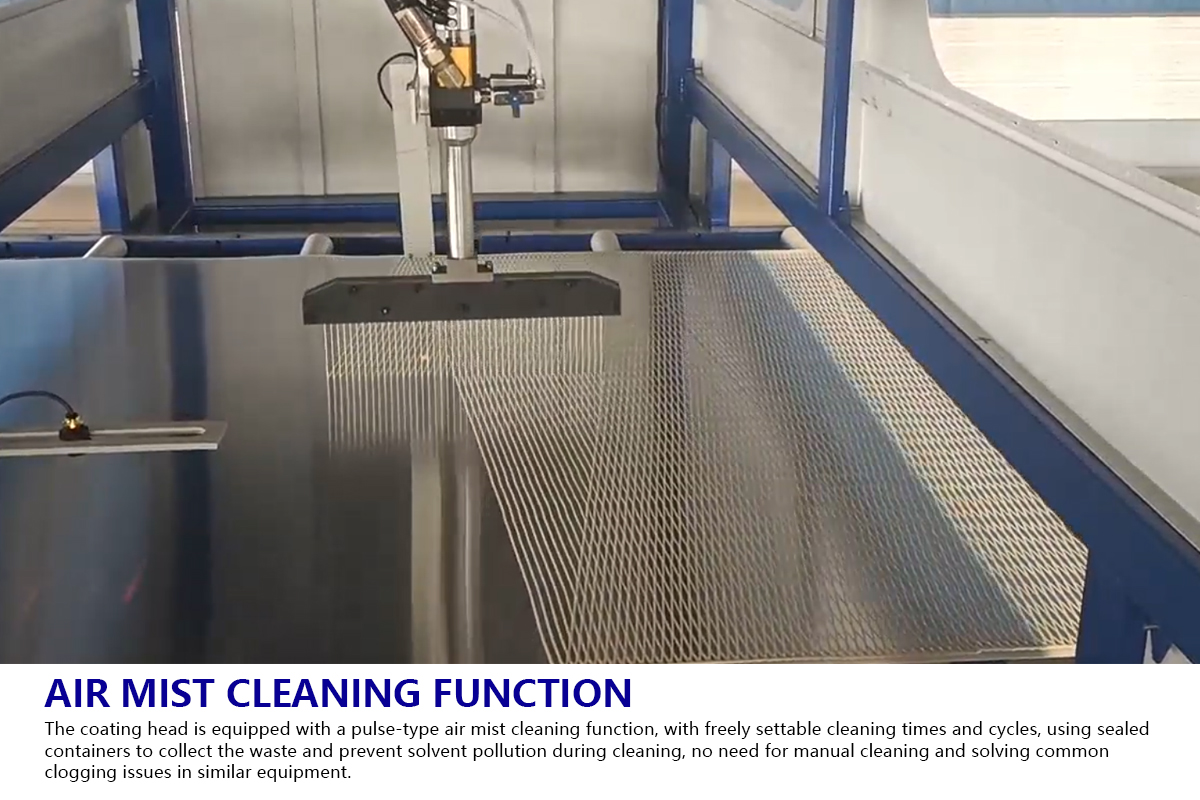

| Glue Usage | Accurate data on glue usage per square meter allows for strict control of costs, precise glue ratio, and uniform coating without waste | No accurate data on glue usage, difficult to control the actual amount used by workers, prone to incorrect ratios and high waste | Taking Hebei Hanglong Kaogel as an example, the equipment production speed is 7.5 square meters per minute, and the glue output is 2400 grams per minute, that is, the glue consumption per square meter is 320 grams | ||||||||||

| Automatic Cleaning | Automatic cleaning function, solvent collected centrally, no environmental pollution | No cleaning device, high waste of glue containers, production environment prone to contamination | |||||||||||

| Production Efficiency | The production speed of the equipment is 1-5m, and the maximum production efficiency is 10 ㎡/min | It took three or four people more than 10 minutes to scrape the glue manually. | |||||||||||

| Comparative Advantage | Automatic coating, compared to manual scraping, has the advantages of higher efficiency, reduced glue costs, and labor costs | ||||||||||||

Leave Your Message

Write your message here and send it to us

简体中文

简体中文