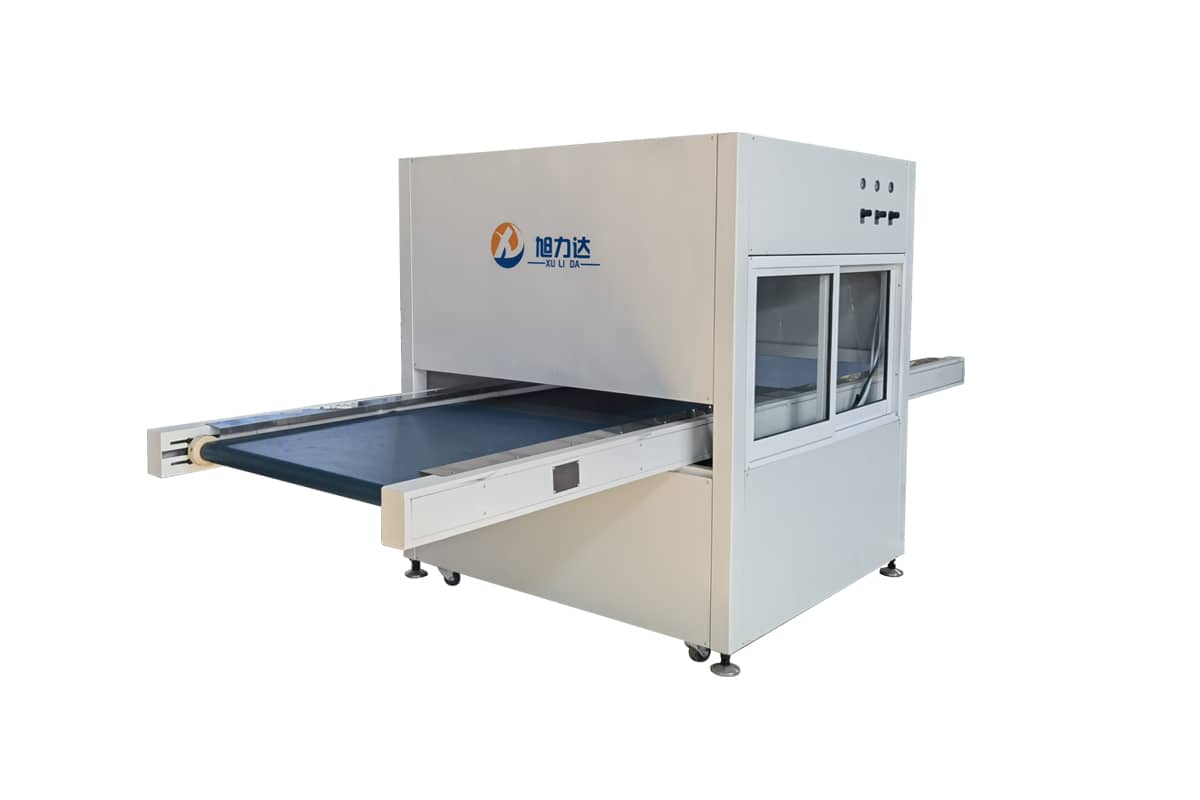

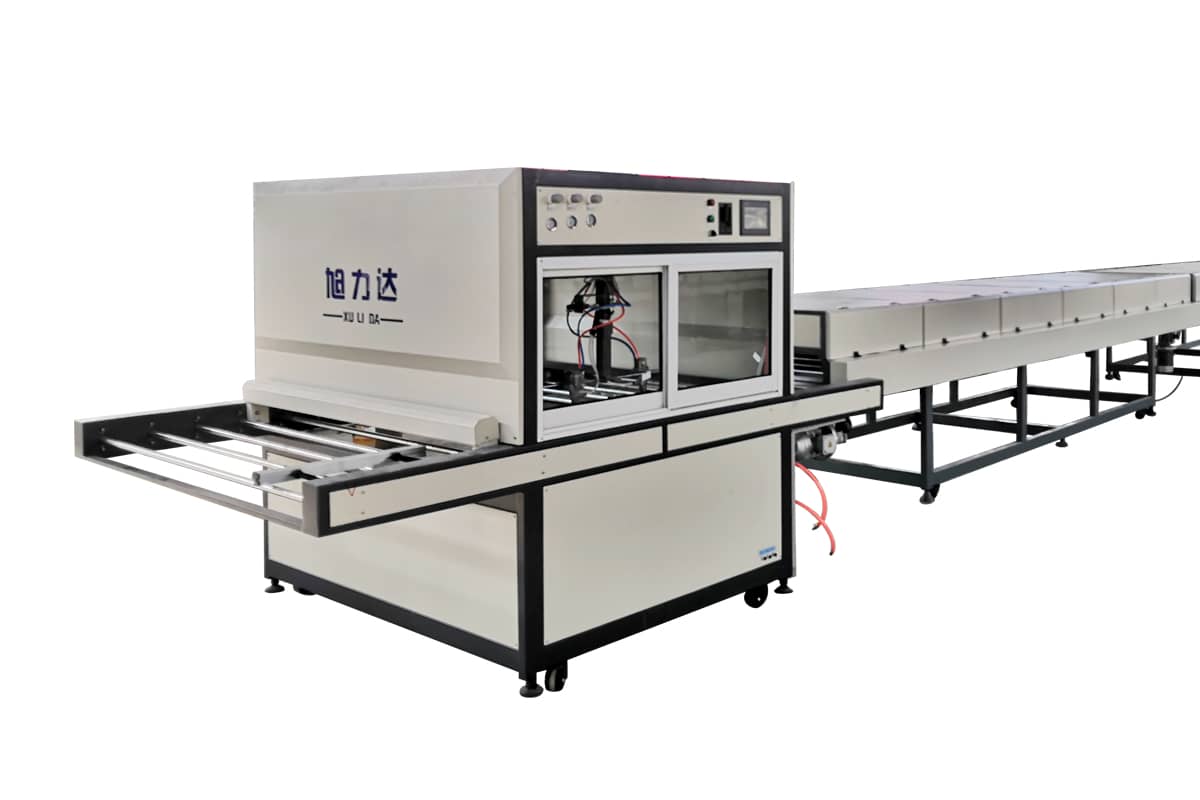

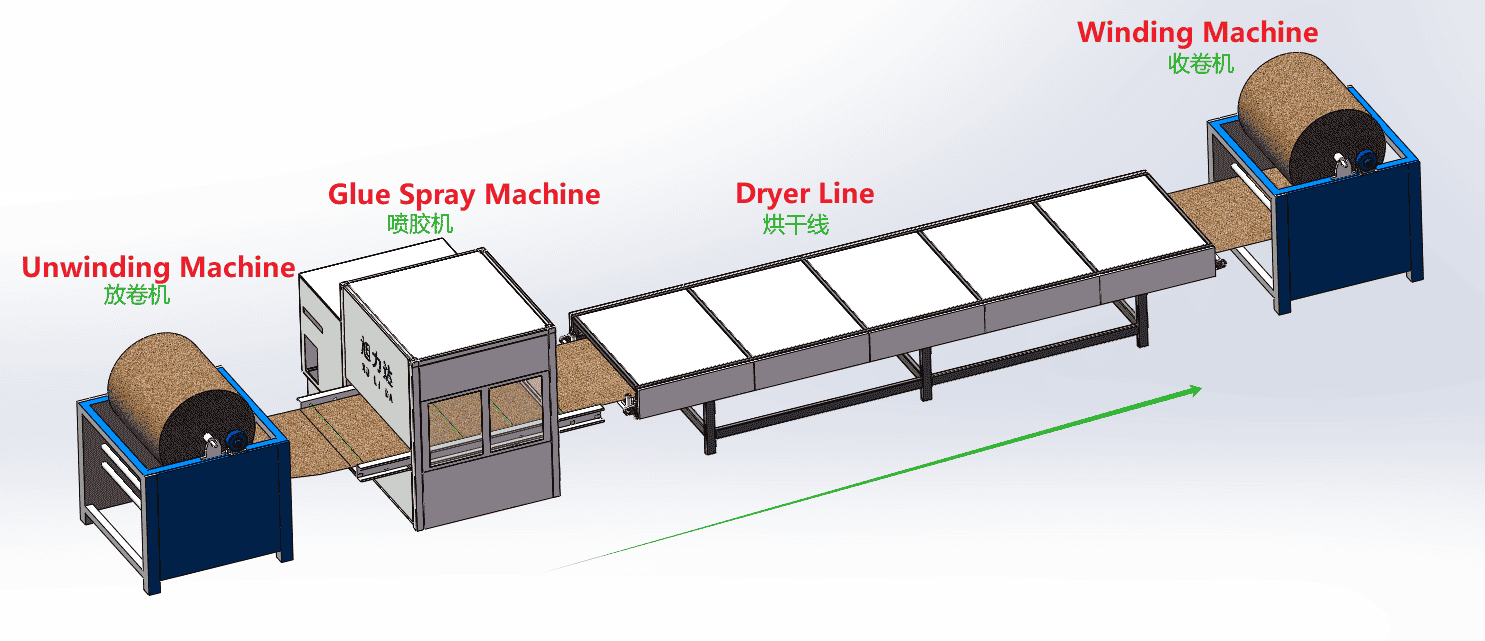

Glue Spraying Machine Production Line

Analysis of Automatic Coating and Manual Scraping Processes

| Category | Automatic Coating | Manual Scraping | ||||||||||

| Coating Method | Single operator can complete automatic proportioning, glue mixing and glue spraying | Requires at least 3-4 people for mixing and scraping, and the scraping is uneven | ||||||||||

| Glue Application Precision | In the coating process, the distance from the edges of the board can be controlled to prevent glue spillage and ensure aesthetic appearance | Manual coating can lead to edge contamination due to uneven application | ||||||||||

| Glue Usage | Accurate data on glue usage per square meter allows for strict control of costs, precise glue ratio, and uniform coating without waste | No accurate data on glue usage, difficult to control the actual amount used by workers, prone to incorrect ratios and high waste | ||||||||||

| Automatic Cleaning | Automatic cleaning function, solvent collected centrally, no environmental pollution | No cleaning device, high waste of glue containers, production environment prone to contamination | ||||||||||

| Production Efficiency | The production speed of the equipment is 8m/min. Calculated based on a board width of 1.2m: 8m / 1.2m / 60min / 8h = 4600 square meters. | 8 hours a day by manual scraping;about 1000 square meters; | ||||||||||

| Comparative Advantage | Automatic coating, compared to manual scraping, has the advantages of higher efficiency, reduced glue costs, and labor costs | |||||||||||

Leave Your Message

Write your message here and send it to us

简体中文

简体中文